Category

PGY series slurry pump

PGY series slurry pump

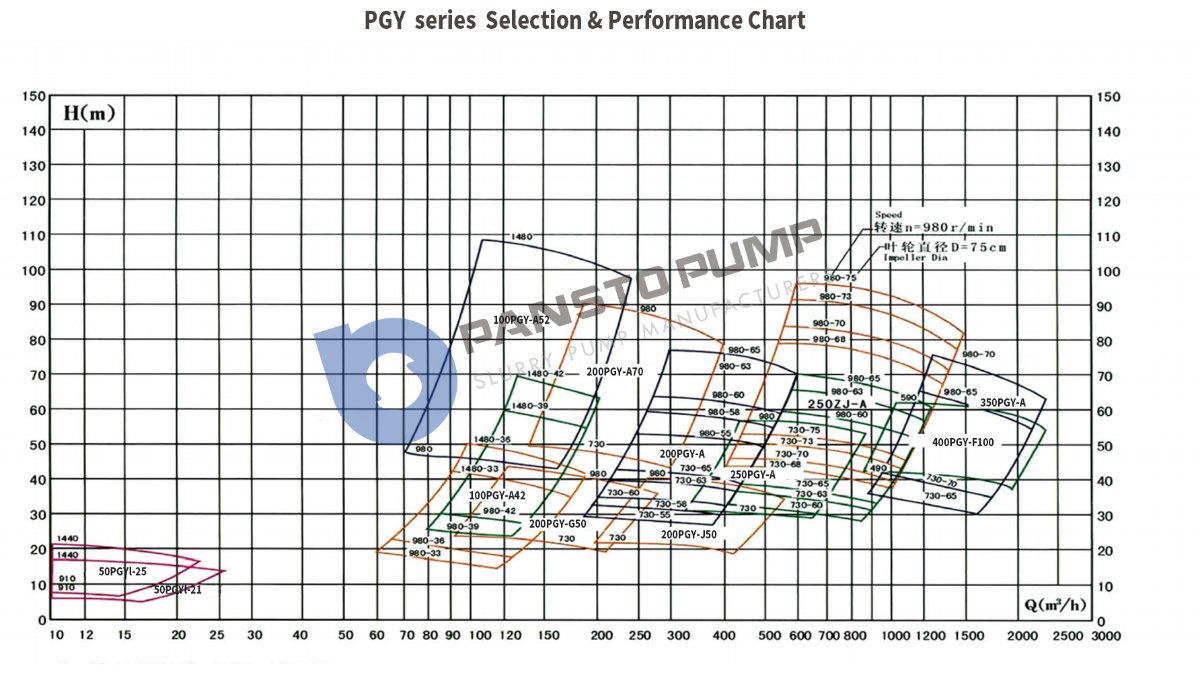

With the development and improvement of impurity pump technology, our company combines the feedback experience of users and uses the theory of modern fluid mechanics, modern mechanical theory and computer software design technology; Our company has launched PGY series slurry pump, which has the characteristics of complete model, wide coverage of performance and working conditions, convenient selection and so on.

Category:

Keywords:

PGY series slurry pump

E-mail:

- 产品描述

-

Product Description

With the development and improvement of impurity pump technology, our company combines the feedback experience of users and uses the theory of modern fluid mechanics, modern mechanical theory and computer software design technology; Our company has launched PGY series slurry pump, which has the characteristics of complete model, wide coverage of performance and working conditions, convenient selection and so on.

This series of products are designed as single-stage, single suction, centrifugal horizontal slurry pump. According to the outlet diameter, the horizontal pump is divided into 350mm, 300mm, 250mm, 200mm, 150mm, 100mm, 80mm, 65mm, 50mm, 40mm and other specifications; The pump of each specification and diameter has different impeller diameters for selection according to the head requirements.

This series of slurry pumps are innovative in hydraulic design and structural design. The flow passage parts are made of self-developed abrasion resistant high chromium wear-resistant alloy cast iron, which has the remarkable characteristics of high efficiency, energy saving, long service life, light weight, reasonable structure, reliable operation, low vibration, low noise and convenient maintenance.

The pump body adopts double pump shell structure to facilitate the replacement of overflow parts; According to the pressure requirements, the outer pump shell adopts nodular cast iron or gray cast iron, and the inner pump shell adopts high chromium wear-resistant white cast iron or cast steel.

Scope of application

PGY series slurry pump is mainly applicable to electric power, metallurgy, coal, building materials, chemical and other industrial industries. It is mainly used to transport abrasive slurry containing solid particles, such as concentrate and tailings treatment in concentrator, ash removal in power plant, slime and dense medium coal preparation in coal preparation plant, slurry transportation in coastal river mining operation, etc. The maximum weight concentration of slurry that can be treated is: mortar 45%, pulp 60%; It can be operated in series according to the needs of users.

Seal form

PGY series slurry pump can adopt two shaft seal forms: auxiliary impeller and packing combined seal and mechanical seal.

Technical Parameters

Model Distribution power P(KW) Flow Q(m³/h) Head H(m) Rotational speed n(r/min) Efficiency η% Cavitation allowance NPSH(m) Maximum particle size (mm) Weight(kg) 400PGY-F100 220-560 860-2339 37-63 490-590 77.6 4.4-5.8 96 5465 350PGY-A95 185-450 464-1826 15.3-65.2 300-590 81.1 3 88 5265 350PGY-A95 185-400 441-1735 13.8-58.8 300-590 78.1 3 88 5220 350PGY-A90 185-560 505-1844 21.2-79.9 400-730 82.8 3.9 85 5005 350PGY-A85 160-450 477-1742 19-71 400-730 79.8 3.8 85 4965 350PGY-A70 185-630 635-2333 16-77 490-980 80.4 3.9 92 3560 350PGY-A65 160-500 589-2166 14-66 490-980 77.4 3.7 92 3531 350PGY-A56 75-250 395-1560 9.7-46 490-980 80.9 3.5 96 3030 300PGY-A103 250-710 402-1573 30-110 400-730 74.5 2.8 69 5085 300PGY-A96 185-560 403-1466 25-94 400-730 77.8 3.5 69 5035 300PGY-A90 160-450 378-1374 22-82 400-730 73.8 3.4 69 4980 300PGY-A85 220-800 376-1504 30-129 490-980 77 3.5 76 4530 300PGY-A83 220-800 367-1469 29-123 490-980 75.5 3.5 76 4514 300PGY-A80 200-710 354-1416 27-115 490-980 73.5 3.4 76 4490 300PGY-A78 185-630 415-1796 21-103 490-980 75 3.2 76 4474 300PGY-A75 132-560 300-1480 20.8-98 490-980 77.5 3 72 3480 300PGY-A73 132-500 292-1441 20-92.4 490-980 76.5 3 72 3466 300PGY-A70 110-450 280-1381 18-85 490-980 75 2.9 72 3446 300PGY-A68 110-450 272-1342 17-80 490-980 73.5 2.7 72 3432 300PGY-A65 90-315 299-1249 15-71 490-980 76.9 3 72 3020 300PGY-A63 90-315 200-1211 14-67 490-980 76 3 72 3008 300PGY-A60 75-560 276-1153 13-61 490-980 73.9 2.8 72 2991 250PGY-A85 160-560 221-907 32-133.7 490-980 70.5 2.8 54 4110 250PGY-A75 110-355 225-900 23-103 490-980 74 3 56 3070 250PGY-A73 110-355 219-876 21.6-98 490-980 73.1 3 56 3056 250PGY-A70 90-315 205-976 19.4-86 490-980 75.6 2.8 56 2465 250PGY-A68 90-315 199-948 18.3-82 490-980 74.6 2.8 56 2453 250PGY-A65 75-250 235-950 16.5-72 490-980 79.6 2.5 62 2323 250PGY-A63 75-250 228-921 15-68 490-980 78.6 2.5 62 2311 250PGY-A60 75-185 218-870 14-62 490-980 83.5 2.5 62 2223 250PGY-A58 55-185 211-841 13-58 490-980 82.5 2.5 62 2214 200PGY-A71 75-220 142-552 22-94 490-980 69.8 2.4 48 2263 200PGY-A70 55-185 93-401 20-91 490-980 62.3 2 37 2245 200PGY-A65 75-200 150-600 17-76 490-980 70.8 2.5 48 2223 200PGY-A63 55-185 146-582 16-71 490-980 69.8 2.5 48 2211 200PGY-A60 45-160 135-550 15-64 490-980 75.9 2.5 48 2203 200PGY-A58 37-132 131-532 14-59.3 490-980 74.9 2.5 48 2033 200PGY-C58 37-110 134-596 12.8-61 490-980 69 2 75 2063 200PGY-A57 37-110 95-427 13-56.3 490-980 67.8 1.8 32 2023 200PGY-A55 37-110 124-504 12.3-53.4 490-980 73 2.3 48 2019 200PGY-A50 30-75 115-460 9.5-43 490-980 76.8 2.5 48 1735 200PGY-A48 22-75 111-442 8.7-39.7 490-980 75.8 2.5 48 1728 200PGY-C42 30-132 142-550 12-63 700-1480 77.1 2.2 69 1605 150PGY-A50 30-160 85-360 20-100 700-1480 69.6 2.5 34 1475 150PGY-A46 30-132 79-331 17-85 700-1480 67.6 2.3 34 1461 150PGY-A42 22-90 66-275 15-70.8 700-1480 71 2.5 35 1075 150PGY-A39 18.5-75 61-255 12.6-61 700-1480 69 2.4 35 1064 150PGY-B42 22-90 83-365 12.7-67 700-1480 71.6 2.5 40 1085 150PGY-A36 15-55 61-245 9.7-50 700-14802 71.6 2 32 1010 150PGY-A33 11-45 56-225 8.2-41.6 700-1480 69.6 1.8 32 1003 100PGY-A52 30-160 51-242 22-110 700-1480 56.3 2.1 21 1465 100PGY-A42 18.5-75 61-204 14-70 700-1480 66.7 2.5 24 1053 100PGY-A39 15-55 57-189 12-61 700-1480 65 2.4 24 1042 100PGY-A36 11-45 46-190 9.6-51 700-1480 67.7 2.5 24 980 100PGY-A33 7.5-37 43-174 8.0-43.2 700-1480 65.7 2.3 24 973 85PGY-A30 4-15 23-79 7.4-34.8 700-1460 63.5 2 19 504 85PGY-A27 3-11 20-71 6-28.2 700-1460 61.5 1.8 19 500 75PGY-A50 22-90 27-111 22.3-110 700-1480 45 3 13 1378 75PGY-A46 15-55 23-94 17-86 700-1480 44.7 1.4 14 1082 75PGY-A33 4-18.5 12-54 7.7-43 700-1480 42 2.9 13 537 50PGY-A19 1.5-11 8-35 12.8-57 1430-2930 58.8 1.3 11 173 50PGY-A17 0.55-7.5 4.5-23 9.4-44.6 1400-2900 52.4 2.5 11 121 Product Diagram

PRODUCT MESSAGE

Pansto Pump

Shijiazhuang Pansto Pump Industry Co., Ltd

Laura Shi:+86 15732149758

Daisy Shu:+86 18033775897

Mail:sales@panstopump.com

Add:Shijiazhuang equipment manufacturing base, Hebei China

copyright © 2022 Shijiazhuang Pansto pump Industry Co., Ltd